My bachelor’s thesis in mechanical engineering at Technical University Munich deals with the challenge of guiding product and service design processes towards sustainable solutions. Therefore I developed a software that accompanies the development with automated life cycle assessment (LCA), analysis and decision support.

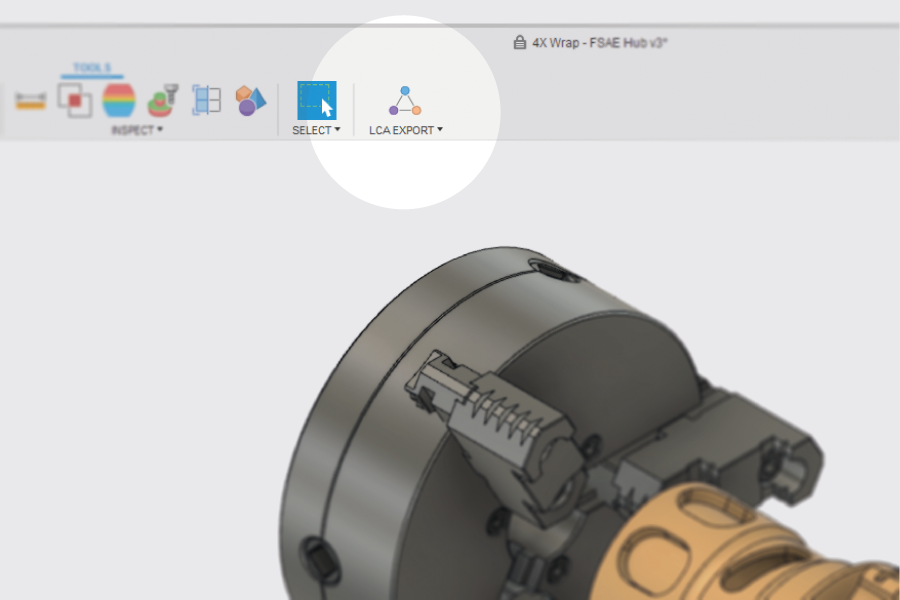

In order to access design data I developed an Autodesk Fusion 360 plugin that extracts materials, geometries, assembly structures, joints and used features.

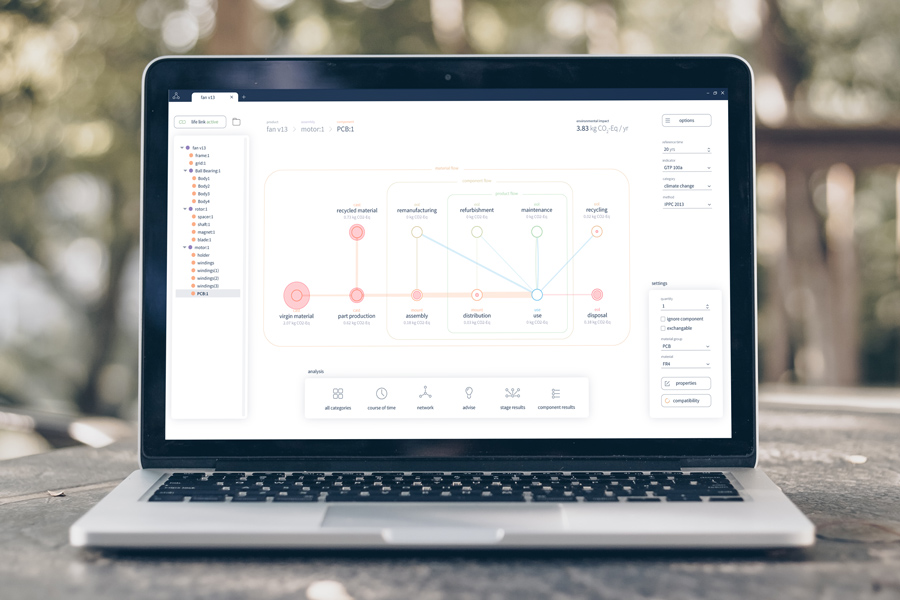

By implementing a life link functionality, changes in the CAD design can be evaluated in the LCD software in realtime.

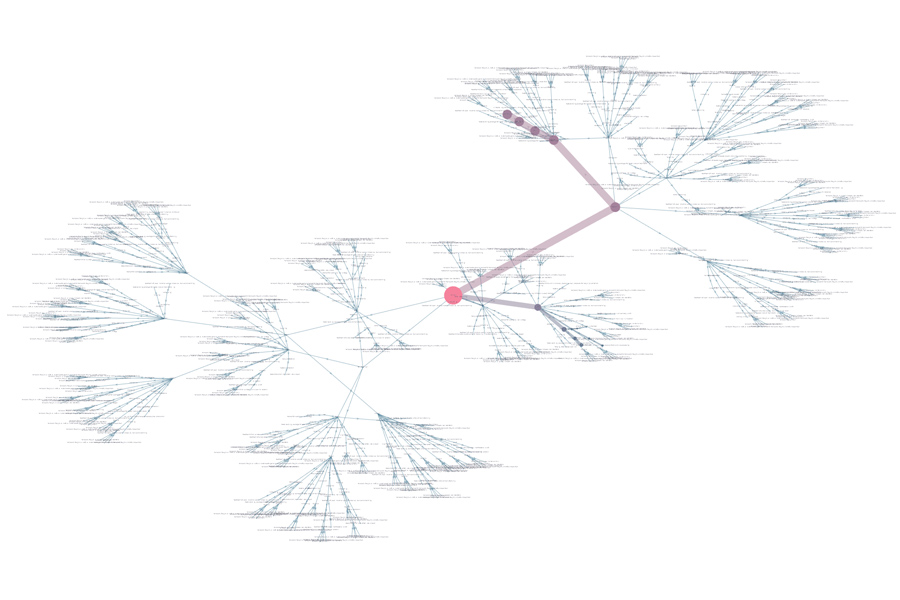

The generated product system, consisting of subassemblies, components, stages, operations and processes can be visualized as interactive flow chart or network. Environmental Impacts are displayed and accentuated with red circles.

The idea of looping product, component and material flows as described in the concept of a Circular Economy is explicitly integrated.

All 51 Life Cylce Impact Assessment (LCIA) methods available with ecoinvent 3.6 are imiplemented in the LCD software. Thereby evaluations of multiple indicators such as climate warming potential, freshwater aquatic ecotoxicity, land and resources use, human health effects and many more can be calculated.

Analysis algorithms assist the identification of important contributers to the environmental impact and help the understanding and effective reduction of environmental effects.

Systematic variiation of design parameters allows for sensitivity analysis and guidance towards suitable design strategies. In this way, sustainability aspects can be effectively integrated into requirement engineering and product development processes.

📅 2019/2020

💼 Technical University of Munich (Bachelor’s Thesis – Mechanical Engineering)

🧔 Felix Laarmann